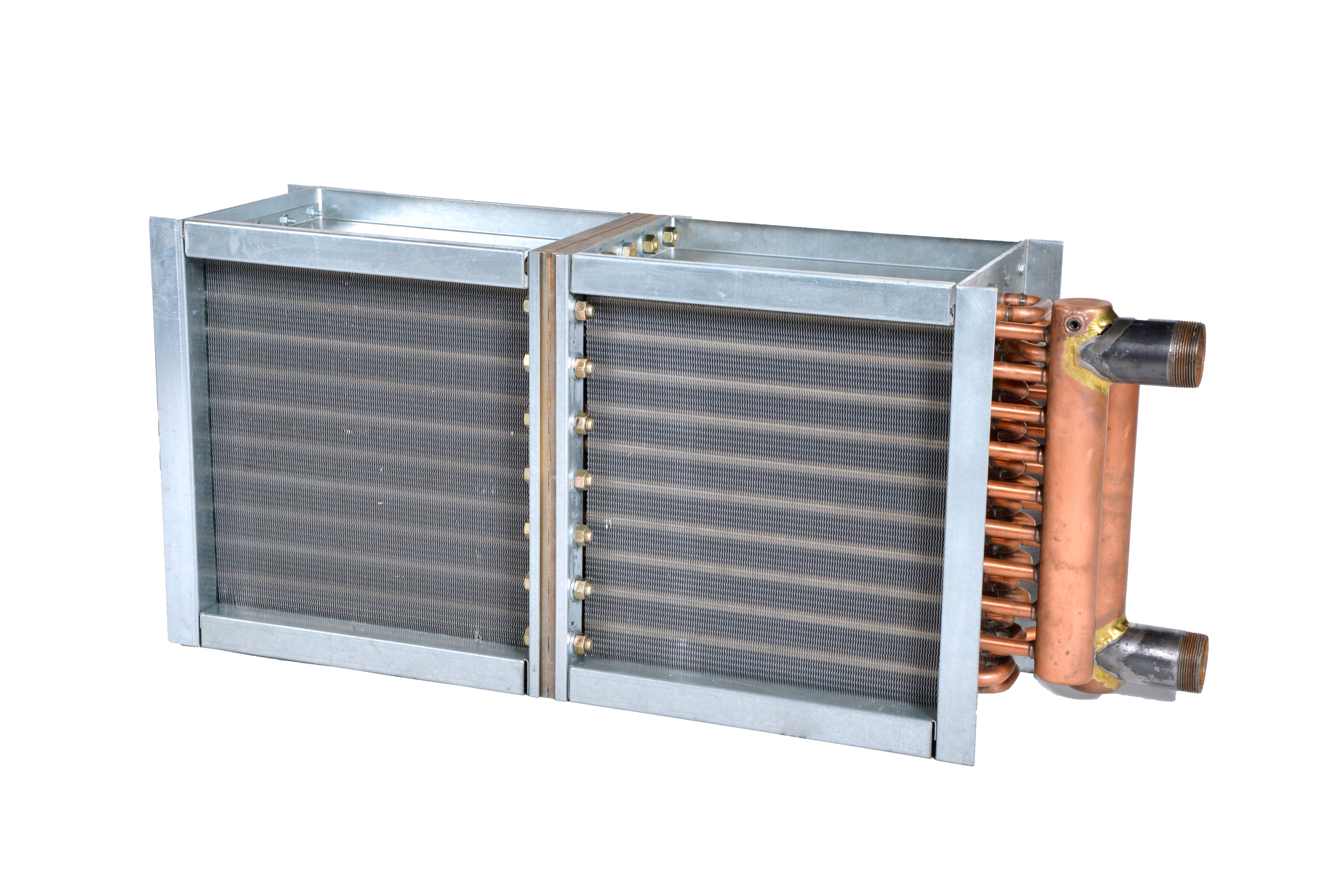

The sectional coils from Coil Company are comprised of two or more sections connected by a gasketed junction plate. These coils are suitable for use with water, propylene glycol, or ethylene

glycol. The coils are leak tested as an assembly at Coil Company at a pressure of 150 Psig. The maximum operating pressure recommended for these coils is 75 Psig.

Instalation

Sectional coil installation should follow the same guidelines as standard water or glycol coils with the restriction that the coil is installed level with the coil ends and each section junction firmly supported. Failure to adequately support the end or the junctions may result in leaks at the junction plates. If sectional coils are stacked, then each coil will need to be adequately supported, and the coil ends and the junction plates. It is important that the lower coils do not carry the weight of the coils.

Assembly

The sectional coils will ship from the plant fully assembled when possible. This is done to ensure no damage occurs to the tube extensions at the junctions as well as to keep contaminants from

getting into the coil. Disassembly may be required at the job site.

Design Specs

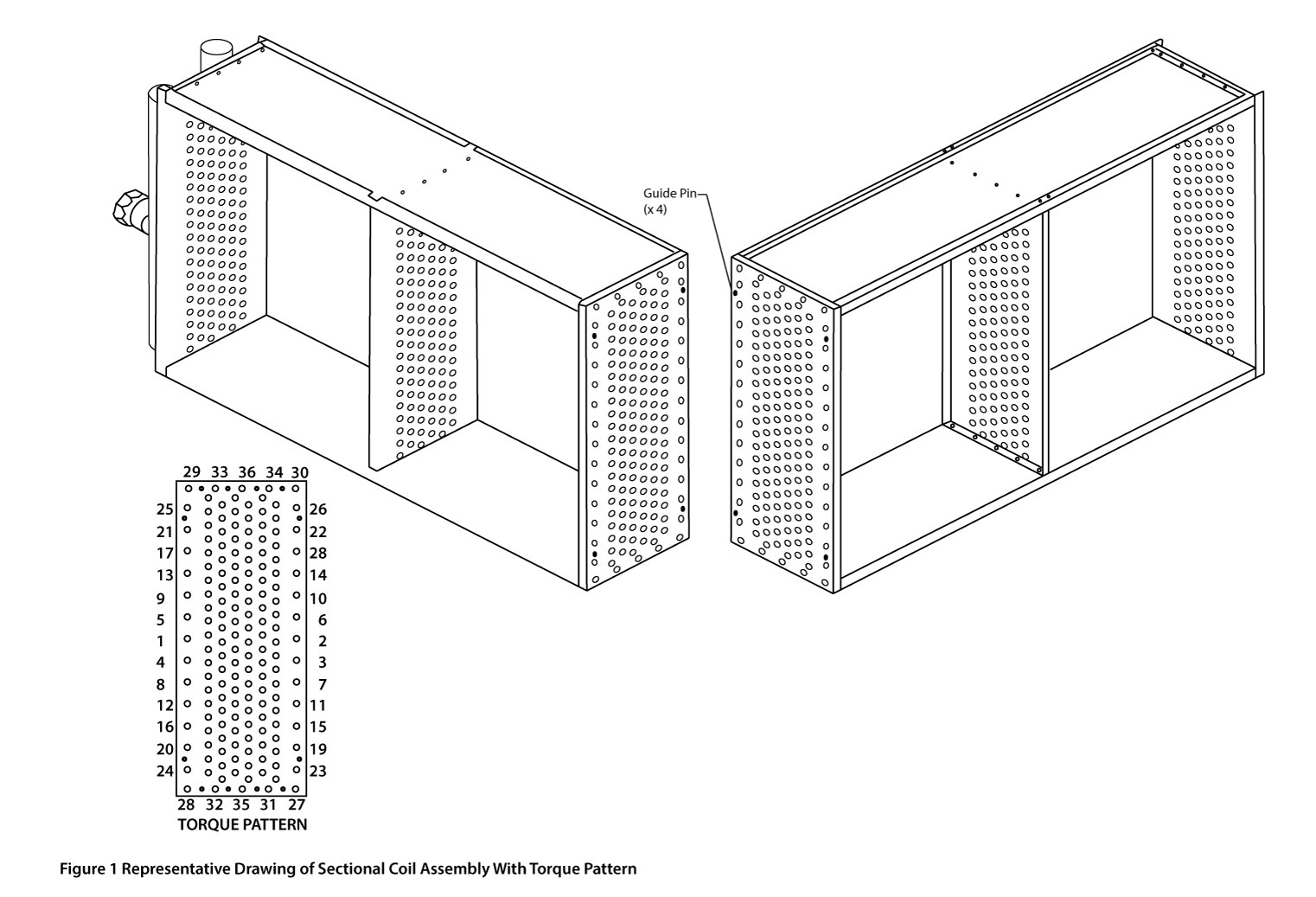

This design incorporates a front header end and a back-return bend end that are sealed together in the middle of the length of the coil. Essentially, this gives you two sections that are about half the length of the original coil. There are matching tube sheets at one end of both pieces, as well as gaskets, that allow for a fluid-tight connection where the two sections meet.

Standard Sectional Coil