There are many reasons why hot water coils in your system can under-perform. Some reasons are from the time of the design, and many other instances can also occur after the coils have been installed. Here are 10 common reasons why hot water heating coils can fail:

- Air stratification issues – The air flow across the surface of the coil is not being evenly distributed. This is often seen in duct mounted heating coils, because the duct transition before or after the coil is not long enough to allow for uniform air flow. Remember: Duct air velocity is anywhere between 1,000 and 1,400 FPM velocity, and the transition into the coil normally needs to slow that velocity down to 500 to 650 FPM.

- Lack of air flow – This can happen in all coil systems, but it usually occurs in older systems. Systems need to be checked every few years to be sure the downstream fan and motor drive package are supplying the needed air flow.

- Laminar flow – This means that the velocity of the water is so low along the inside walls of the tube that you lose the ability to transfer heat from the water to the air. This problem is indigenous to smaller duct coils that have less than 500 CFM. Many times, it’s the system designer who specifies a water volume (GPM) that’s so low it creates laminar flow. The water velocity needs to be 1 (FPS) and many times it’s less than half that velocity.

- Valves and piping accessory malfunctions – Valves, piping lines, air vents, etc. all need to be checked each season to be sure the design water flow is being delivered to the coils. Often, air is trapped inside the coil and takes up heat transfer space. The output of your coils will be decreased when air is inside the coil.

- Coil fouling – This occurs when filters upstream of the coils are not properly maintained. The air side finned area receives foreign material that lodges itself deep inside the coil surface. Air flow travels to the path of least resistance, because the build-up is not uniform. The foreign material diverts air to other portions of the coil and acts as an insulator that further reduces heat transfer.

- Higher loads – This happens many times over a period of years. A system may have an actual leaving air temperature of a coil of 85 degrees F, when it requires 95 degrees F. This may be an original design problem or added loads over the years. You would need to increase the water volume to this coil and live with the higher water pressure drops associated with the water volume increase.

- Reduced water volume and temperature – The coils in question don’t receive the volume of water because the pumps are undersized, and the system can’t pump the needed water flow to the coils furthest away from the heating source. A system may produce water temperatures five to ten degrees below design.

- Light duty coils – Coils need to be replaced after numerous problems in small commercial tonnage air handlers. These coils can be 3/8” OD x .012 wall tubes, .004 thick fins, very light duty headers and return bends, and can have leak problems in a matter of a few years after initial installation.

- Freeze coil damage – These coils require all the air introduced into them to be fresh air. After numerous freeze events, the coils have been repaired so many times that coil circuits have been eliminated and much of the fin surface is gone. When you bypass a coil tube, many times three or more tubes can also be bypassed, reducing coil capacity. After numerous freeze events, coils are repaired and have leaks reappear within weeks or months. The walls of the tubes and bends are irreparably damaged, and it’s just a matter of time before post freeze event leaks appear.

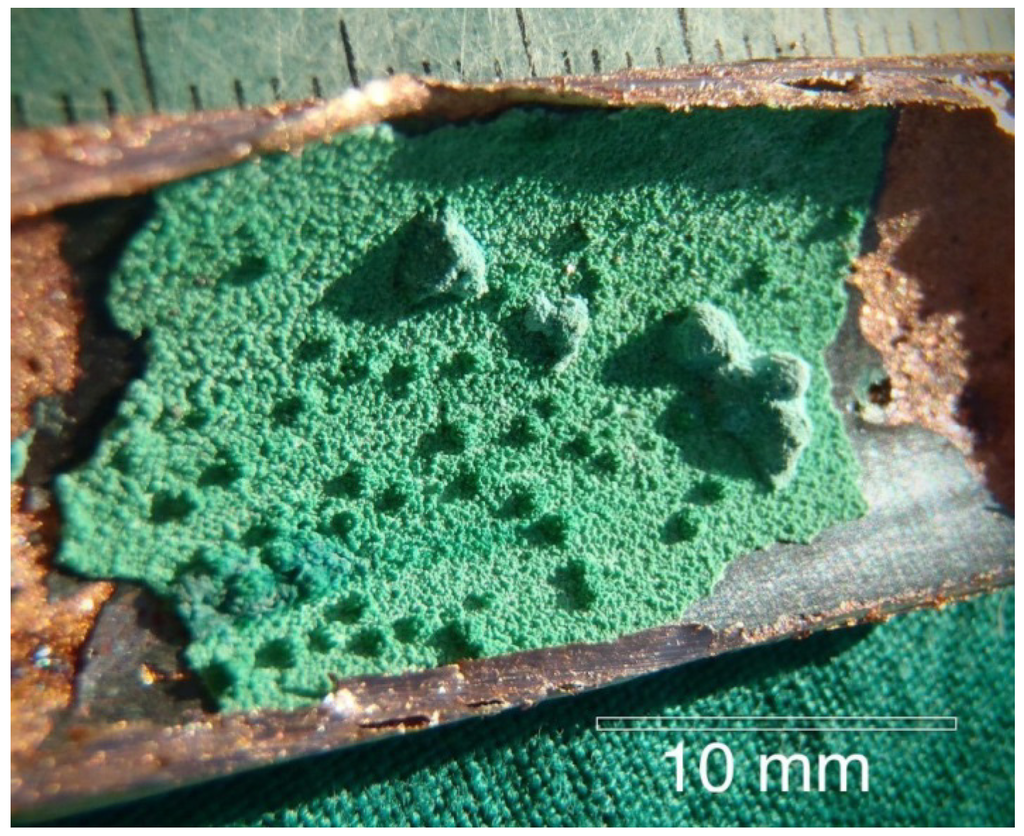

- Corrosion – This is by far the main reason why hot water coils fail to perform in systems and usually need to be replaced. Corrosion on both air and water side of the heat exchanger appears over time.

Water side has a treatment process, and this process can produce corrosive agents that finally reach a level where they can attack copper or aluminum. You need to specify that your testing company look for these corrosive agents in the water, because the standard tests do not show them. If you see pitting, irregular holes usually in the bottom half portions of tubes, this may indicate water side contamination.

Air side corrosion usually happens with known contaminants in the air. You can see discoloring of the fin surfaces. Salt corrosion occurs with units located near marine environments. These are the most prominent cases of corrosion, and you can see a white ring forming around the coil tubes that is eating away the aluminum fins where it meets the copper tube.